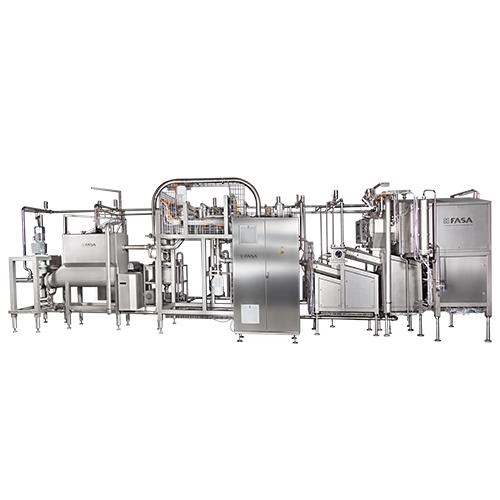

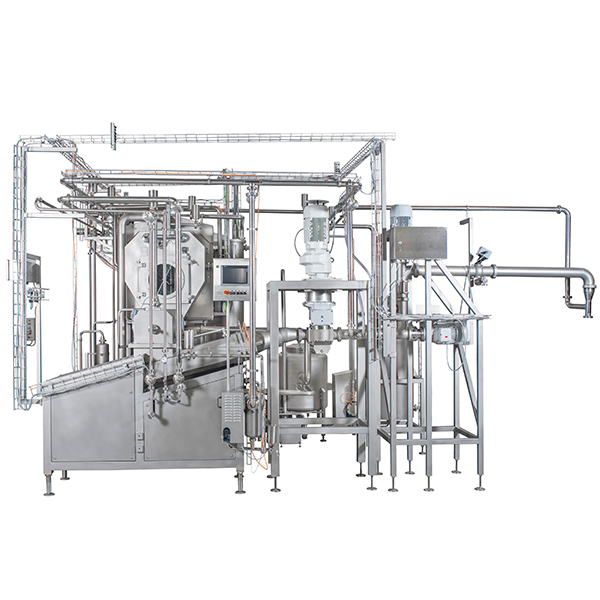

Continuous Butter making Machine

Continuous Butter Making machine for butter production from ripened cream. Different modification machines process up to 10 000 l/hour of cream.

Main features

- Continuous butter making machine for butter production from ripened cream.

- Machine’s output – up to 10 000 l/hour.

- Butter milk fat content – up to 0,5 %.

- Cream fat content 35 up to 42 %.

- Continuous Butter Making machine consists of:

- Cream beater;

- Churning section and separation drum;

- Kneading section 1, with vacuum chamber, with light;

- Kneading section 2;

- Butter milk collection tank with level control;

- Butter milk pump for recirculation and pumping out;

- Tube type exchanger for butter milk cooling;

- Internal piping.

- Design for easy maintenance.

- Built up design for each processing stage with frequency-controlled drives.

- CIP cleaning.

Contact us now and get the most suitable offer for you!

Video

Benefits

HAS DIFFERENT DOSING UNITS

Butter making machines can be equipped with different kinds of dosing units: for moisture, culture, oil (for spreads production), dry ingredients (herbs, cacao etc.) and salt slurry. Moisture level can be measured and controlled automatically with a special moisture metering system.

CAN GO DIRECTLY TO PACKAGING MACHINE

Butter produced with a continuous butter maker can be fed with a butter pump first to a butter silo of the required capacity, and then to the packaging machines or bulk filling machine.