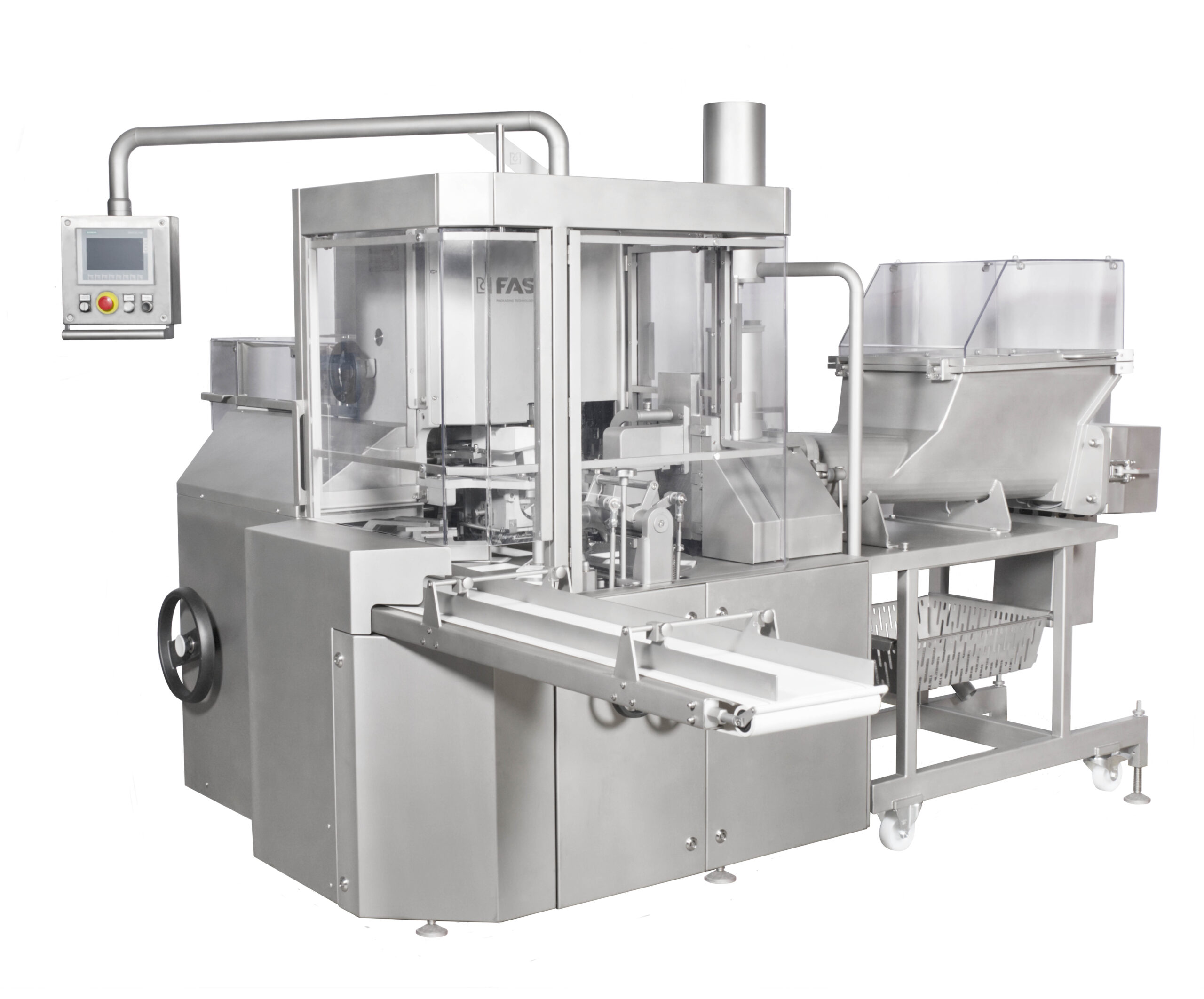

ARM-B4 - Butter filling and wrapping machine

ARM-B4 is designed to fill and wrap butter and margarine in aluminum foil, parchment paper or ecoline.

ARM-B4 machine can dose 500 – 1 000 g (1-2 lb), capacity up to 20 packs/min.

Main features

- Packing paste type products into consumer size portions.

- Applicable products: butter, margarine, spreads, edible fats, curd.

- Type of dosing – volumetric.

- Two product feeding options: hopper with augers or direct feed from the production line via resting tube.

- Sizes of package: 500 – 1 000 g (1-2 lb), capacity up to 20 packs/min.

- Easy to shift between portion weight by changing the height of brick, height adjustable by handle, the adjustment points are marked with a ruler.

- Shapes of bricks: rectangular.

- Folding type of package: bottom folding.

- Product input temperature: butter +10….+14 °C, margarine +8….+14°C.

- Packaging materials: aluminum foil laminate, parchment paper, ecoline (with memory).

- PLC and HMI with Touch Screen.

- Fully automatic lubrication system.

- Pneumatic compensator.

- Stainless steel dosing unit.

- Pneumatic rotor switch.

- Stainless steel table with synthetic inserts.

- Machine body covers from stainless steel.

- Machine safety covers in accordance with CE safety requirements.

- Two sensors for foil tracking (roll width control; end of the roll).

- Foil centering device with photocell.

- UV lamp.

- Belt driven foil broaching shaft instead of chain.

- Stationary foil roll spindle.

- CIP except dosing unit (optional).

- Possible printers (optional): Ink jet or Thermo-printer.

Video

Benefits

RELIABLE PACKING MACHINE

The base model ARM machine has been in production for more than fifty years and is of a proven design. More than 8 300 models have been delivered worldwide. ARM-B4 machine was modernized in 2017. We achieved optimally simplified and reliable technological solutions that allow to operate and maintain the equipment easily and to meet the needs of a modern dairy plant.

ACCURATE DOSING

The machines fill and wrap such products like butter, margarine, edible fats, curd or other products of paste type consistencies with a certain filling level. The dosing device accurately fills the formed bricks avoiding a product leakage. Easy to shift between portion weight by changing the height of brick, height adjustable by handle, the adjustment points are marked with a ruler.

INTEGRATED SOLUTION

Improvement of packing by the integrated end of the line solution: semi-automatic case packer DSU is available for the end of the line packaging into cartons.