ORG - Bulk butter filling machine

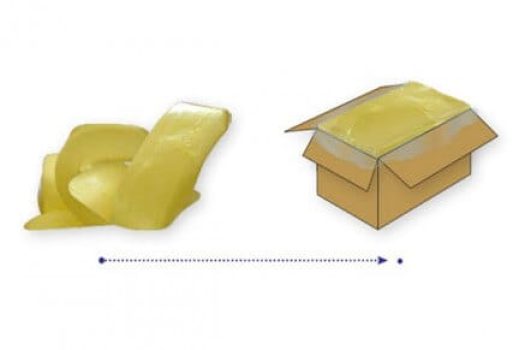

Bulk butter filling machine ORG is a semi-automatic filling machine designed for filling into pre-made boxes (bag-in-box).

Main features

- Semi-automatic filling machine for the bulk filling into pre-made boxes (carton or plastic).

- Applicable products: butter;

- Type of dosing – extruder volumetric.

- Machine’s output: up to 150 cartons/ hr.

- Weight of box: 5-10 kg, 15-20-25 kg.

- Product input temperature: +9….+16 °C.

- PLC and HMI with buttons and switches.

- Pneumatic box turn-back system.

- Replaceable dosing head for second box size (optional).

- Pneumatic set of automation: cutter and box pusher (optional manual cutter).

- Digital scales for weight control (optional).

- Auxiliary transporter (optional).

Contact us now and get the most suitable offer for you!

Video

Packages

Can be filled with

Frequently Asked Questions

Can we pack with this machine not just butter but also margarine, spreads, curd and other oils?

The Bulk Filling machine ORG is used just for packing butter. This machine fills box from side so any more liquid product will run out.

What is the maximum capacity of this machine?

The maximum capacity of Bulk Filling machine ORG is up to 151 cartons/h.

Can we pack 5 kg and 25 kg on the same machine?

Yes, you can fill different boxes if you have replaceable dosing head for different box sizes. You will need three heads – one for 5 kg , one for 10 kg and one for 15, 20 and 25 kg.

Can we easily change box format, weight on this machine? Do I need to change any part for that?

It depends whether you want to change your format between 5 kg, 10 kg or 15 and 25 kg or you want to change it between 15 and 25 kg. If you want to change your format between 5 kg, 10 kg and 15-25 kg you do need to replace dosing heads. But if you want to change from 15 kg to 20 kg or 25 kg then you do not need to replace a dosing head.

How can we know that the box is filled enough or not too much?

There is an option to buy Bulk Filling machine together with scales and transporter for smoother work.

Is there an option to even box weight after filling and weighing it?

No, if there is too much or too little product in a box, you have to even the weight manually by taking of or adding more product.

What possibilities are there for equipment delivery?

It is possible to get bulk filling machine ORG in 3-5 months of delivery.

What are the possibilities for equipment shipment?

These are to be agreed – it varies up to the Customer’s needs according to Incoterms 2020. It can be shipped by sea, air or roads. It can be delivered to the convenient Port for customer (CIF) or prepared to pick up from FASA warehouse (EXW). Variety of choices to be agreed.

Do you provide warranty and after sale service for this equipment?

We provide a warranty for all equipment we manufacture. To ensure reliable and long-term operation, we carry out the installation and commissioning of our equipment. Commissioning begins once the equipment has arrived at the customer’s facility and the site is ready for installation. During this process, our technicians train the customer’s staff in proper operation and maintenance of the machines. In the event of equipment failure, we supply the required spare parts and provide after-sales service.

Do you provide spare parts?

We supply a set of spare parts sufficient for one year of operation and offer the option to purchase a spare parts set for two years. The standard spare parts set includes sealing rings, gaskets, bearings, springs, and similar components. This allows customers to replace parts quickly and easily. Any additional spare parts can be supplied by FASA as required. We also offer upgrades and improvements for previously manufactured machines. As FASA machines are developed by our in-house R&D team, after you give us an ID of your machine, we are able to provide customers with additional options and technical upgrades.

Contact us now and get the most suitable offer for you!